Advantages

Water jet cutting distinctive aspects:

-Limited flexibility of technological process

-Heating zones absence

– Mechanical stress full absence

-Possibility for cutting the metal with thickness of 300 mm

– Insignificant quantity or absence of residual flash

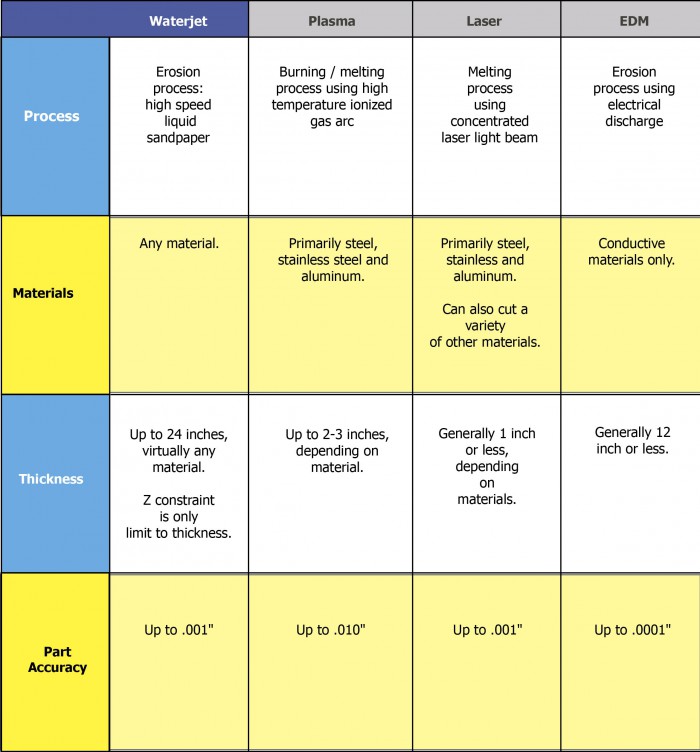

CUTTING TECHNOLOGY COMPARISON

Usual abrasive machines have a problem of backward creep of jet and conicity, which can be minimized by means of cutting speed deceleration. But cutting speed lowering leads to processing cycles duration and cutting cost increasing.

How we solved this problem?

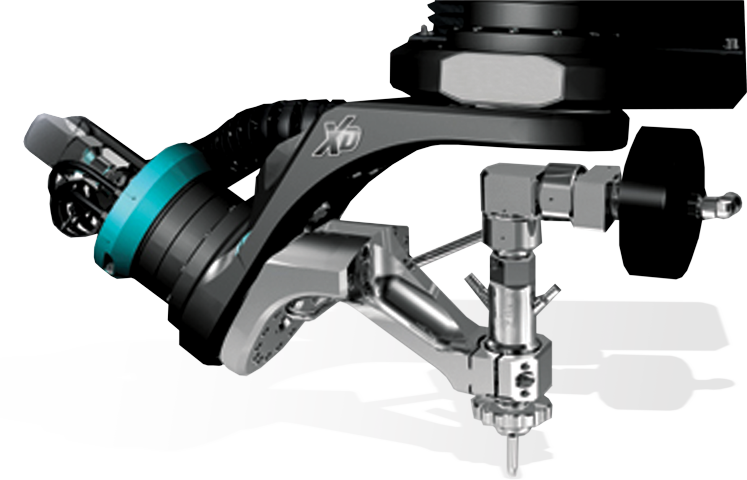

Dynamic Waterjet

More speedy and precise parts processing.

Ambition to exclude of backward creep of jet and conicity of cutting edge laid in the basis of design, created by “Flow” company Dynamic Waterjet technology with active angle regulating of cutting head. The result of these efforts was the possibility of precision cutting without the cutting speed deceleration.

Henceforth backward creep of jet and conicity are not insuperable disadvantage of water jet cutting technology and most universal cutting tool becomes high duty alternative for other types of cutting.

SmartStream™

Dynamic Waterjet uses enhanced mathematic models SmartStream™, that control cutting head automatic tilting angle , providing elimination of conicity.

Supreme cutting quality

Moreover, Dynamic Water jet provides supreme cutting quality, which excludes the necessity of final polishing – cost and time saving.

You shall have an ideal part on the first try.