Stone waterjet cutting

The demand for natural stone rises in the modern world. Premises and flats, office premises and business areas are being built where different kind of soils are applied. The most common and popular are marble, granite, onychite, travertine. They add esthetic and comfort qualities to premise.

Adorned the premise with natural stone, you will obtain durability, superlative beauty and unique interior. But buying the stone, few people know, that it is possible to make real masterpieces of artifacts for floor, walls, fireplaces etc. They include so called, stone carpets, panels, jacks, lockets, coatings. They have different classification on pattern and styles. Such artifacts are made by means of cutting.

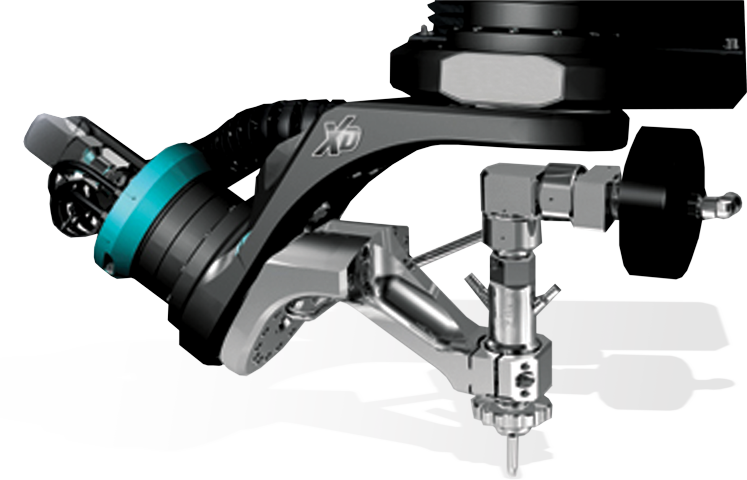

The stone cutting most progressive method is hydroabrasive technology. Hydroabrasive cutting allows top cutting the stone on different axis. The most important thing is a perfect quality of material cut! As for the shivery stone cutting, our equipment has an option of smooth perforation, which doesn’t spoil the material during cutting. Water jet doesn’t create surface stress and heating on the cutting edge, that allows to save original appearance and material strength.

The distinctive feature of cutting using our equipment is a bell les cutting.

Thereby during marble panels manufacturing they no need in further processing, and their joining pass without seams.

- design floor in the office

design floor in the office

- assembly of parts

- marble lattice 20mm

- marble medallion 20 mm

- medallion in the interior

medallion in the interior

- medallion in the interior

medallion in the interior

- marble panels 20 mm

- the assembly process of the marble panels

- marble panel, d=1500mm

marble panel, d=1500mm