screen meshes

The mesh is a consumable item which is used at screening – screen sizing of rock formation and its further grading. Being the screen’s main element, the mesh is used in order to get high performance of screen sizing.

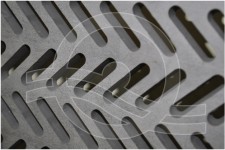

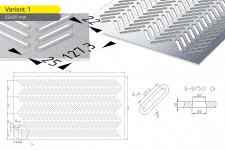

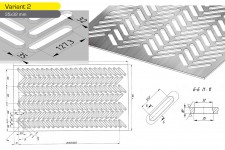

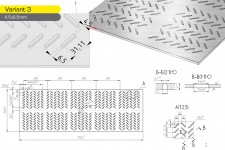

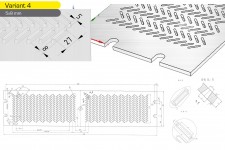

One of our principal directions is production of conical form holes meshes for vibratory screens which are used for agglomerate screen sizing in accordance with customer drawings.

Our efficiency

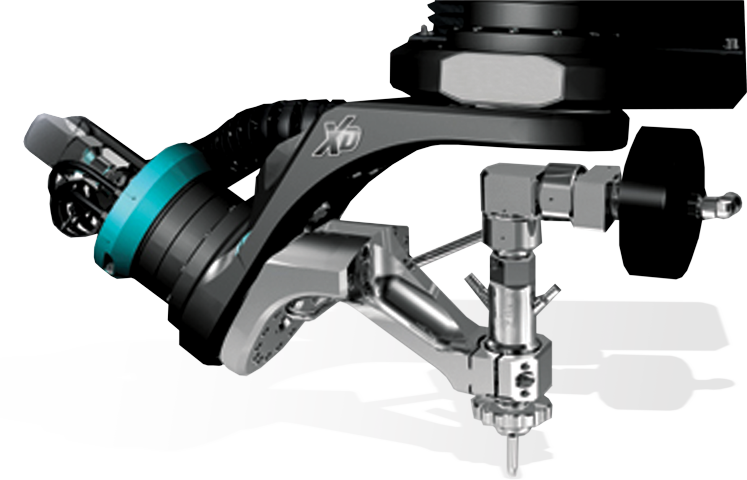

– For production of meshes we use the advanced equipment FLOW Mach 4c with working envelope 2000х4000mm.

– Dynamic Waterjet® technology provides high accuracy: +/- 0.1 mm and high performance (thrice quicker than standard technologies of water jet cutting).

– Dynamic Waterjet® XD technology provides quick 5 axis part cutting with high accuracy of preset angle. The performance range of a cutting head is +/-60о.

– Laser Height Setter Flow – DynaBeam technology allows processing the material with roughened surface.

- SCREEN MESHES

- SCREEN MESHES

- SCREEN MESHES

- SCREEN MESHES

- SCREEN MESHES

- SCREEN MESHES

Jam filtering is one of the most important moment during the technological process of beer production. Brewing syrup output quality depends on it. Filtering process task is thorough separating brewers’ grains from brewing syrup and receiving full extract. It is important to use effective equipment for this process .

Jam filtering is a very important moment when beer production. The process task is to receive the rich extract.

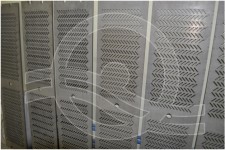

Our company has designed the technology of filter tanks sieves production.

Our sieves have following characteristics:

– type of material is food stainless steel AISI 304, 4 mm

– slot-like gap 0,6-0,8mm

Our sieves advantages:

– «useful» section area – up to 20%

-even raw materials distribution in filtration zone

– excluding of all contamination sources and product quality enhancing

-any size and configuration

– durability

Our clients:

“Heinrich Schultz” Company (Ukraine, Kyiv); LLC “Hrabov” (Barnaul, Russia);

LLC “Orion group” (Ukraine, Kyiv); LLC “Prommontazh-04” (Ukraine, Kharkiv).

- beer sieve D2000mm

- slots 0,7mm

- beer sieve D2600 mm