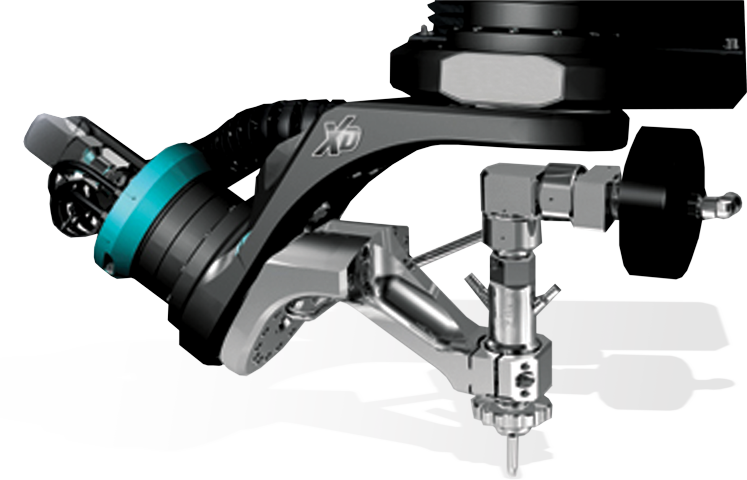

Metal cutting

Water jet cutting technology is used for producing of different steel type tarts (structural, heavy-alloyed, heat resistant), base metal and alloys (titanium and titanium alloys, aluminium alloys, cupper, brass, bronze.

In comparison with mechanical methods (snips cutting, milling, drilling, punching, sawing etc.) and by means of thermal cutting (oxygenic, plasmic, laser-based, electro erosion) advantages of water jet cutting are:

Cutting surface is not exposed to heat

Doesn’t lead to deformation in the cutting zone, as a result of which surface quality is approved.

high metal use factor due to low cutting wide;

various thickness metals and alloys processing.

Metal cutting specification

thickness – from 1 to 300 mm

Cutting accuracy – up to 0,1 mm

Metal hardness – any

Maximum uncut dimensions – 2000х4000 mm

Vertical cutting edge and angular cutting possibility up to 60˚

Absence of metal thermal destroying in cutting zone

- cutting steel 220 mm

- cutting steel 28mm

- cutting stainless steel 15mm

- cutting of stainless steel 20 mm

- cutting brass 2.5mm

- cutting aluminum 12mm

Using our equipment you can obtain different quality of cutting, beginning from the most economical 100 (used as dividing cutting) to the best quality 20. The cutting price depends on selected quality.